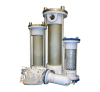

Engineered Filtration System

The FLO-DRI Compressed Gas Scrubbing System is designed for gas conditioning of fuel gas from natural gas wells at the point of use to remove aerosols, contaminants, H2S, moisture, oil and solids.

This process eliminates the costly down time associated with instrument and catalytic heater failure caused by the presence of these substances. The system is engineered for long life, featuring easy cartridge change out, low pressure drop, low maintenance and low cost operation.

For install information, specifications and detailed information, download the PDFs below or Find a Rep. If you are ready to purchase this product for your organization, request a quote by filling out the form below.